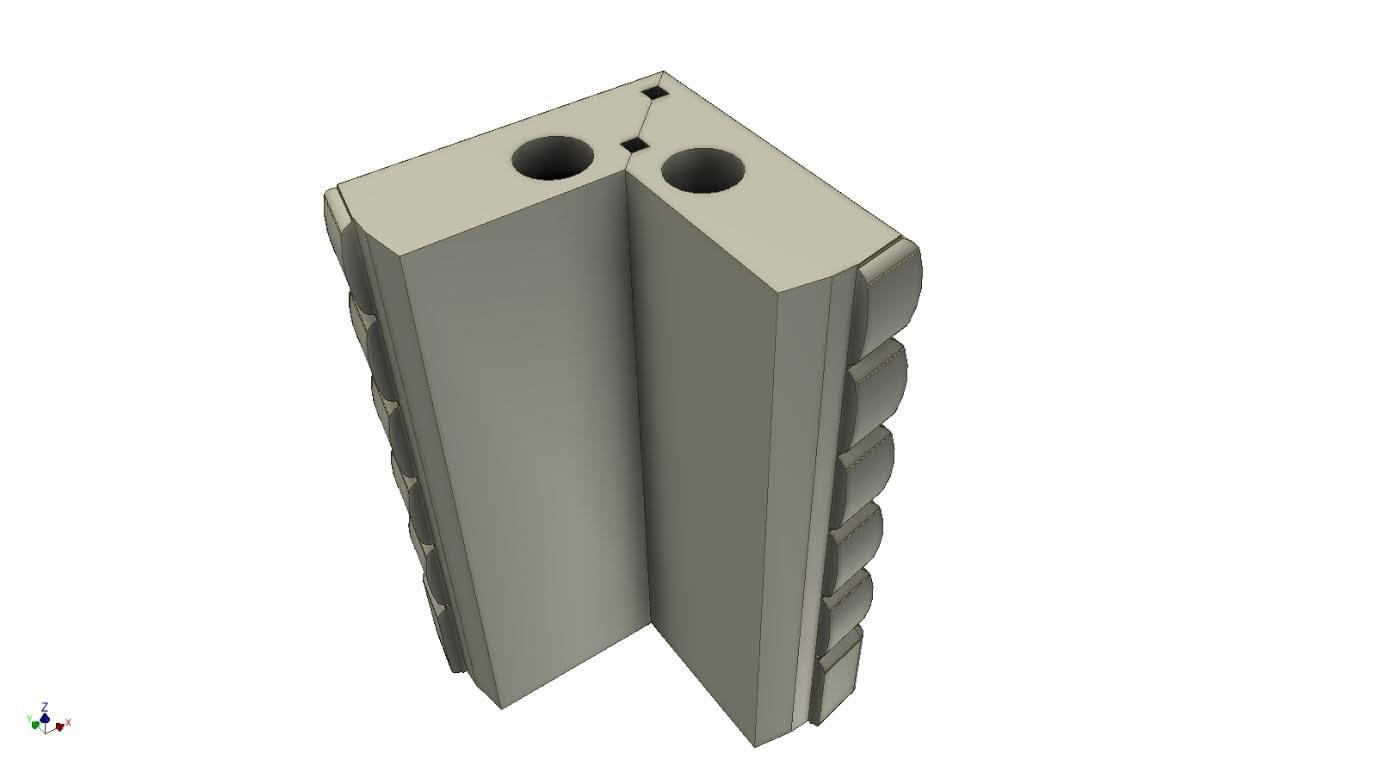

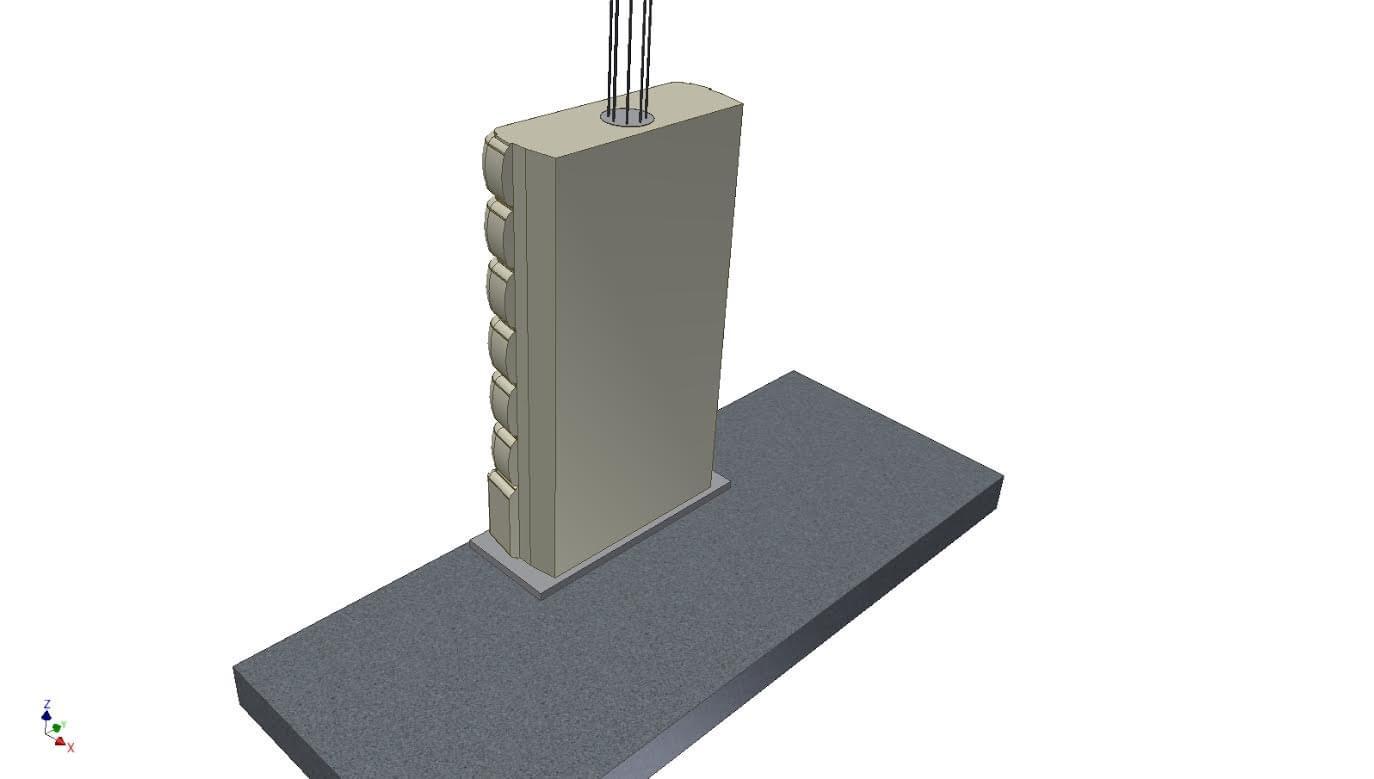

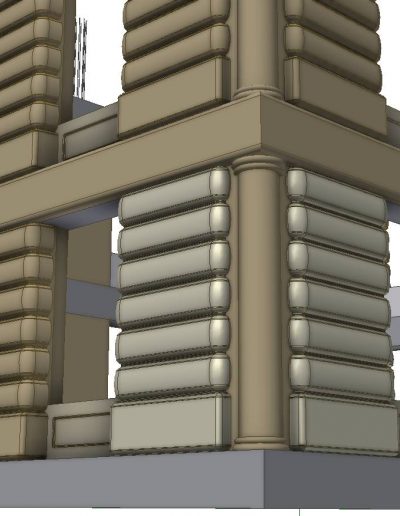

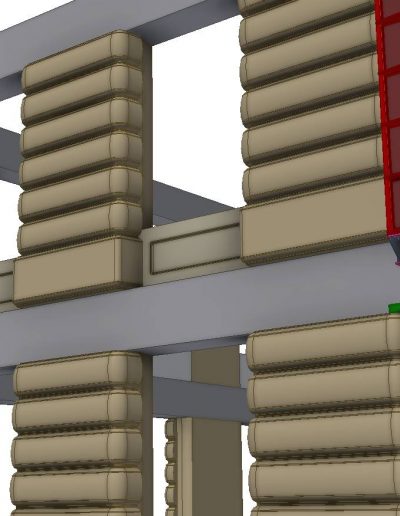

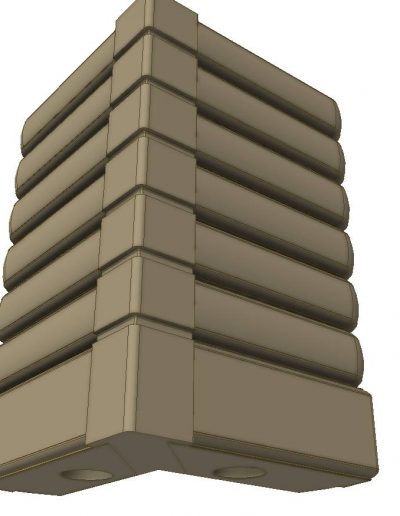

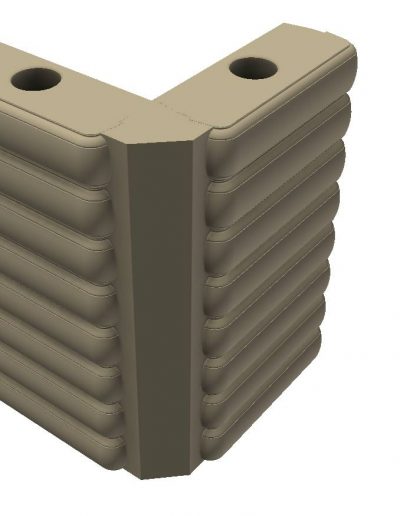

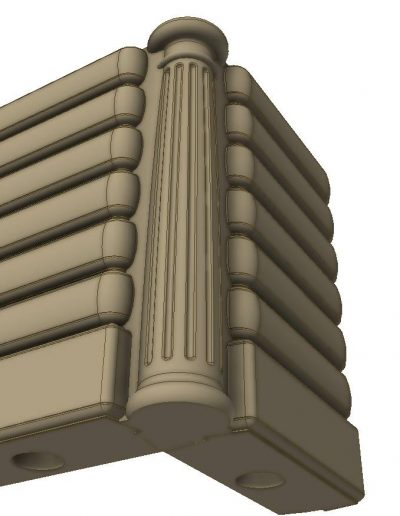

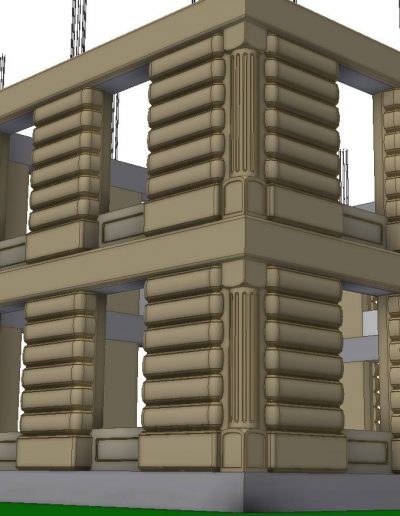

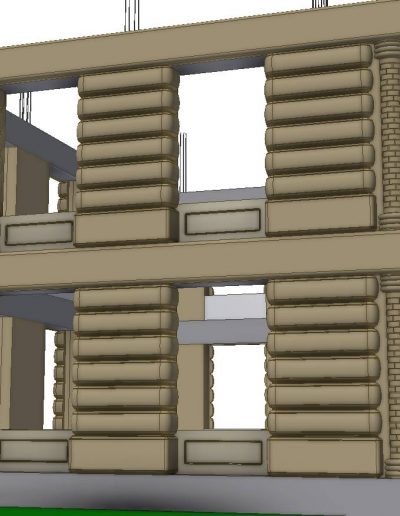

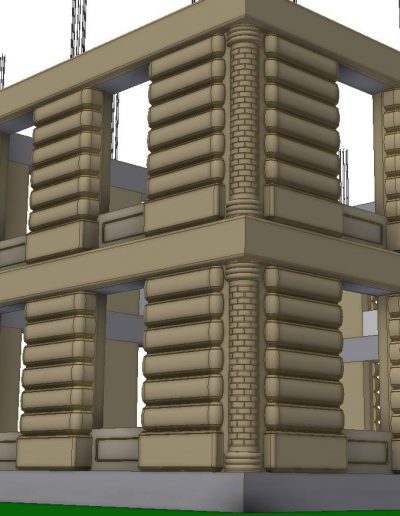

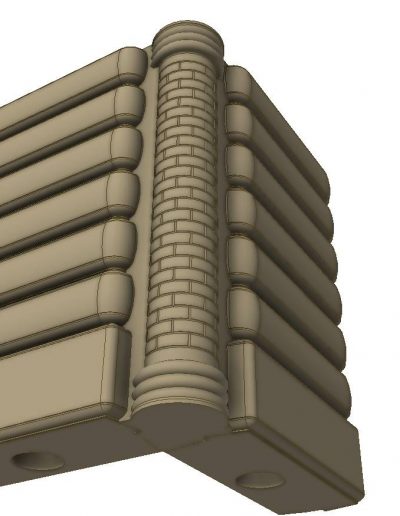

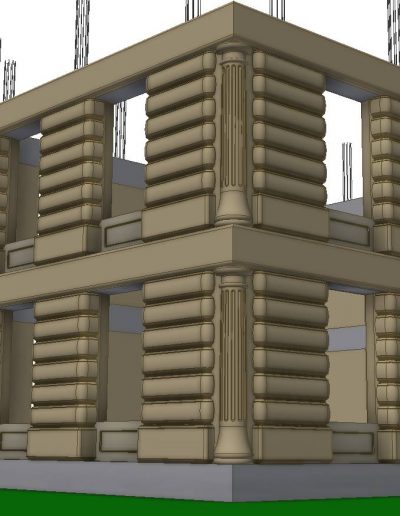

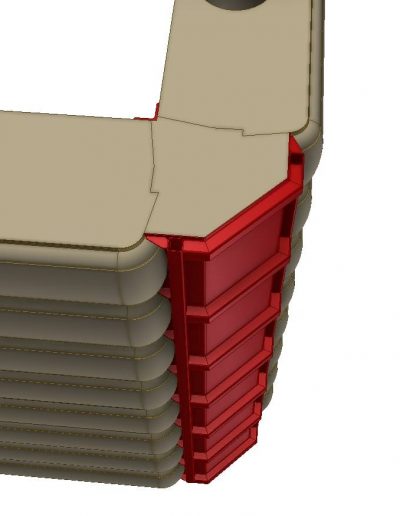

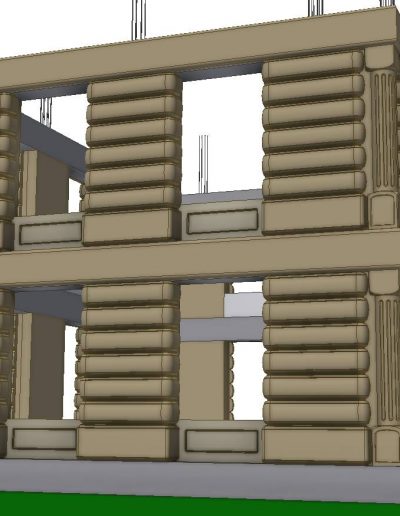

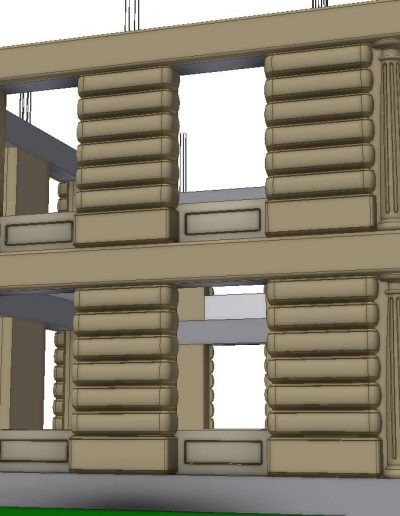

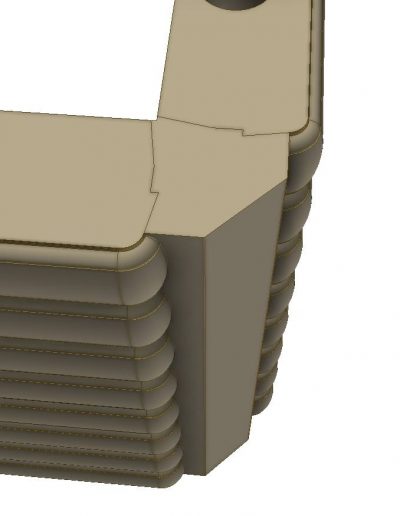

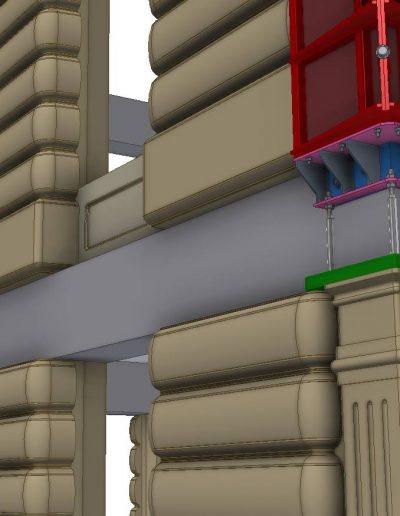

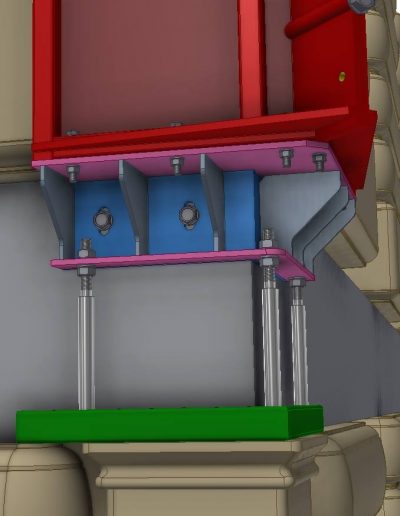

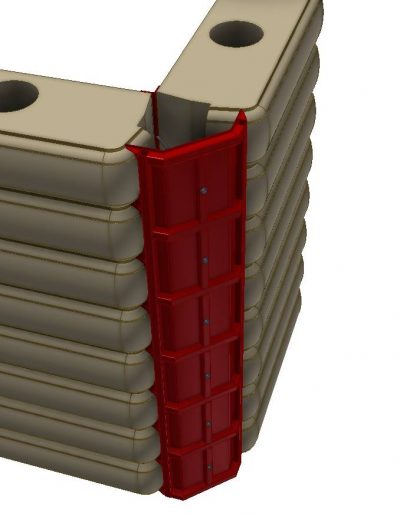

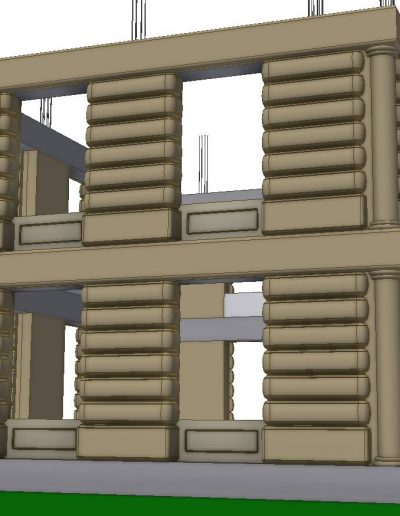

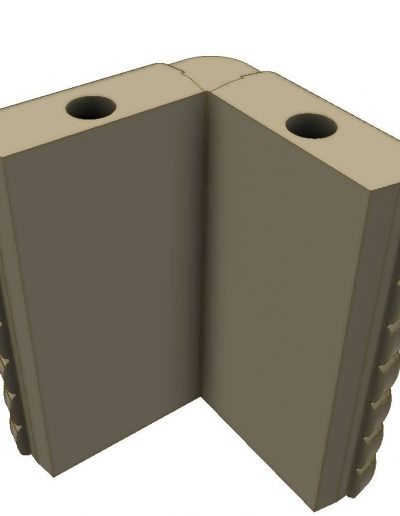

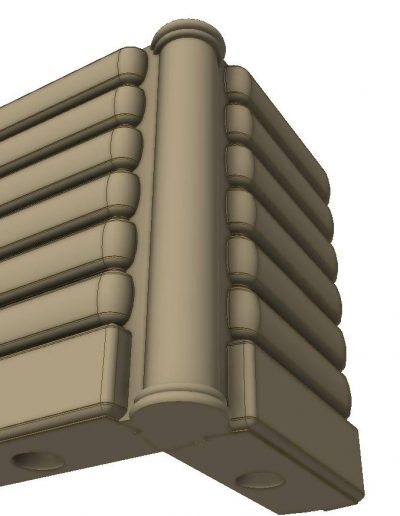

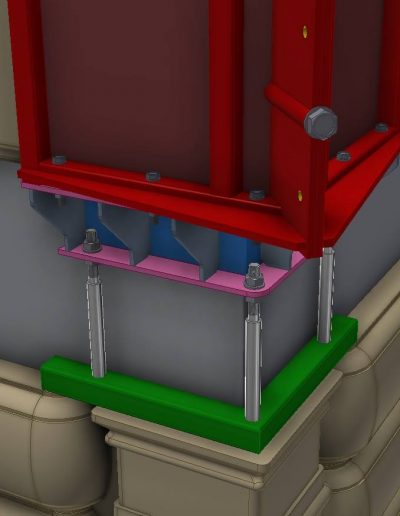

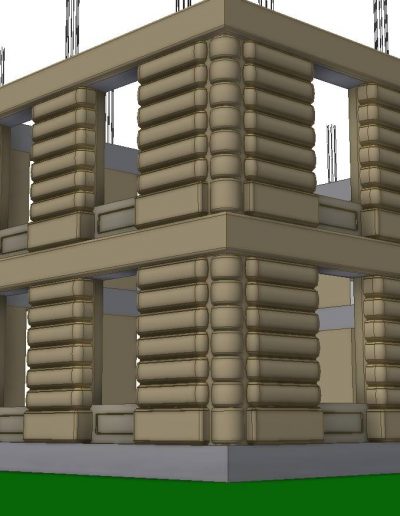

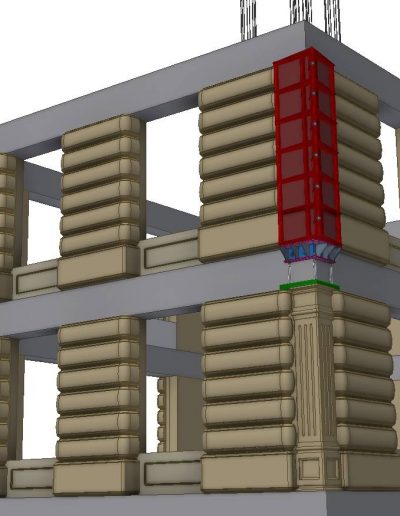

When the panels are formed, a special gap is left for the column. At the construction site, it is literally ‘put onto’ the reinforcing steel of what will become the column. Then the gap with the ‘rebar column’ is filled with concrete. The result is genuine cast-in-place construction: the steel and concrete become a column, and the column is cast to the panel. And the panels themselves are so precise, smooth, and even that they can be joined together safely and easily using adhesive.

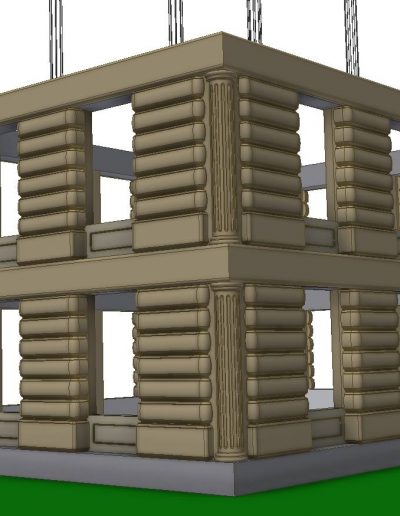

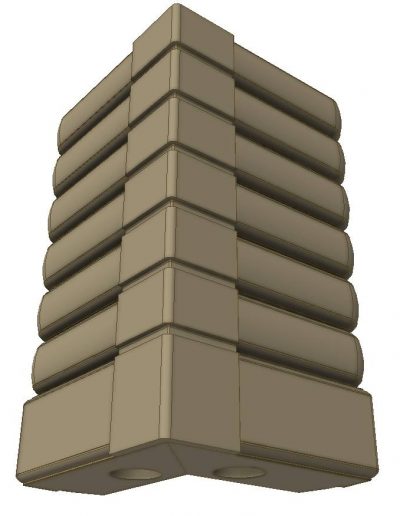

This kind of ‘cast-in-place panel construction’ makes it possible to put up reliable, earthquake-resistant buildings of up to 50 storeys. This is achieved by using normal cast-in-place construction, light outer walls, and a large number of columns around the building’s perimeter: there can be not just one, but two or three reinforced columns inside each wall panel.

With the help of this new technique, a high speed of construction can be achieved. For example, a one-storey building measuring 25×60 meters (1,200 square meters of usable space) was assembled in five hours. And a team of ten construction workers will need only two months to put up a ten-storey residential building.

With the help of this new technique, a high speed of construction can be achieved. For example, a one-storey building measuring 25×60 meters (1,200 square meters of usable space) was assembled in five hours. And a team of ten construction workers will need only two months to put up a ten-storey residential building.

Our technique is based on industrial manufacturing, at a factory that is almost completely automated.

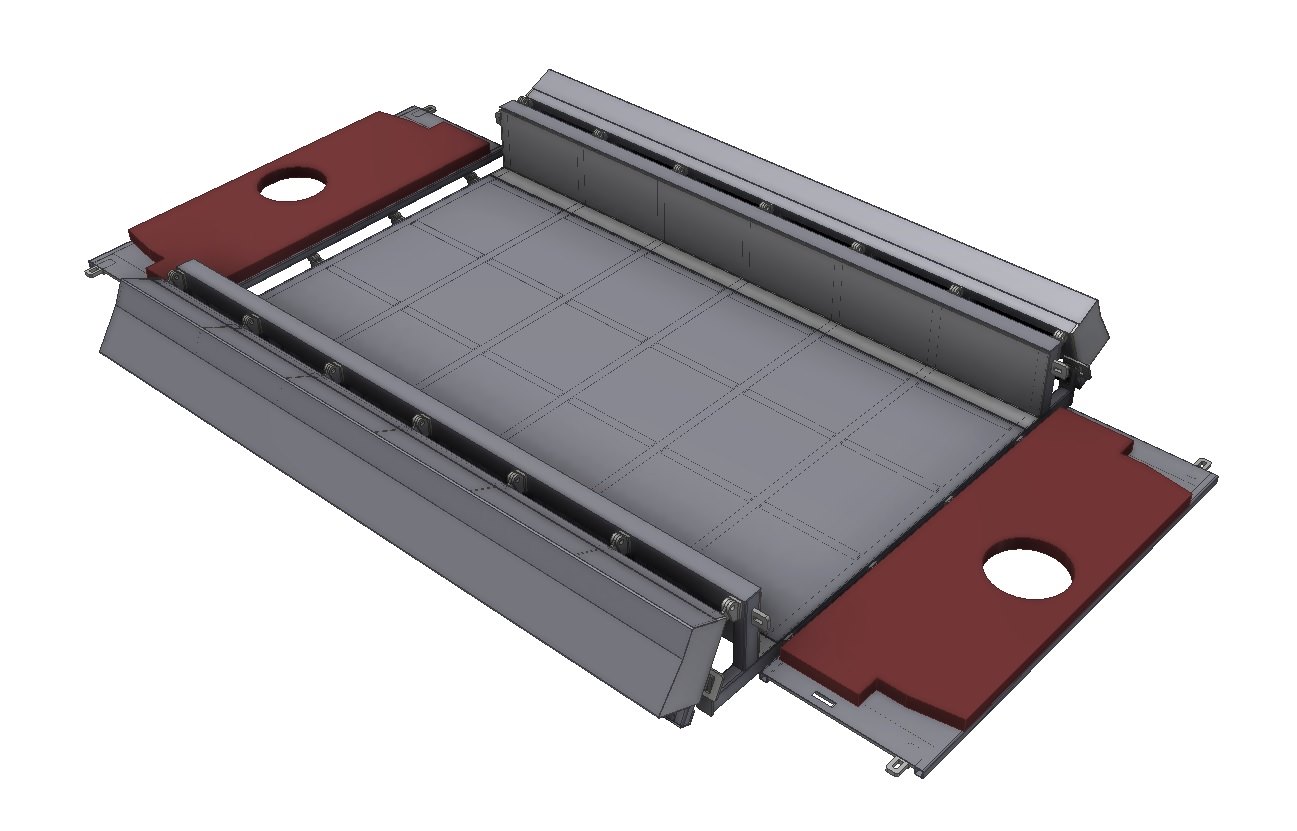

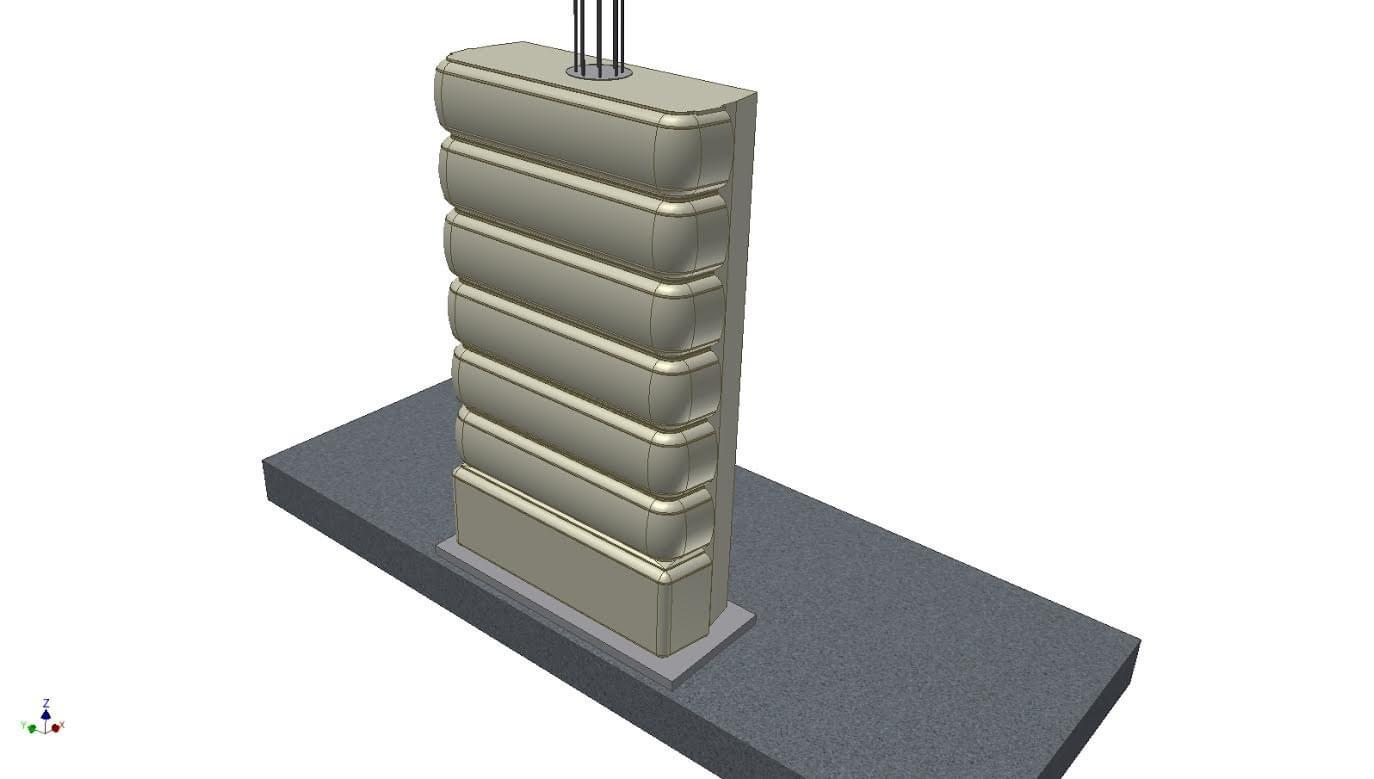

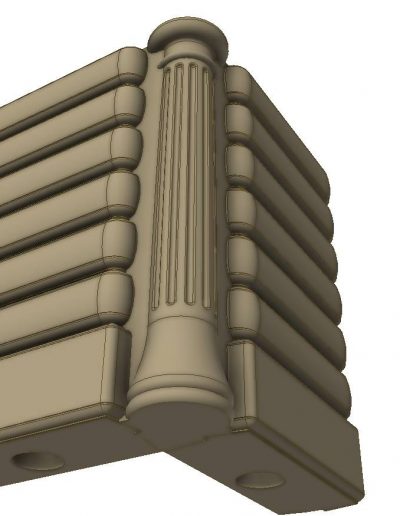

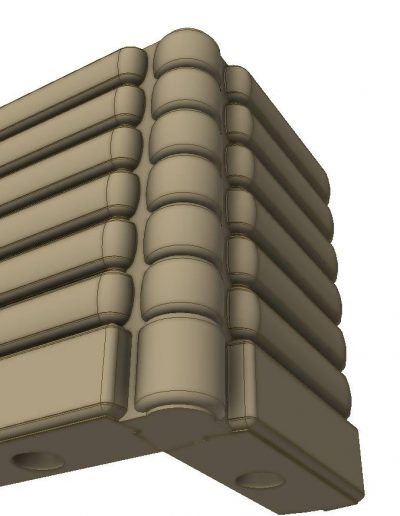

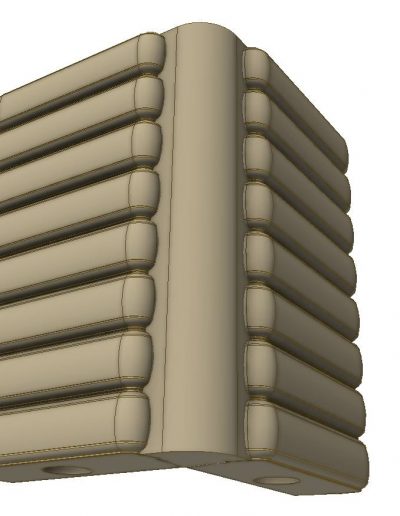

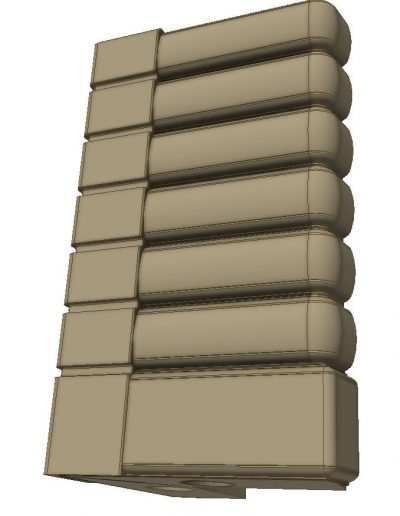

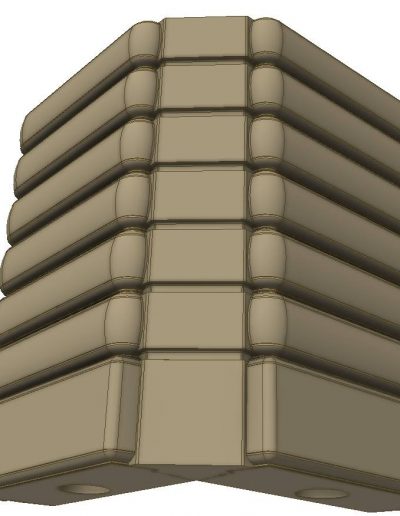

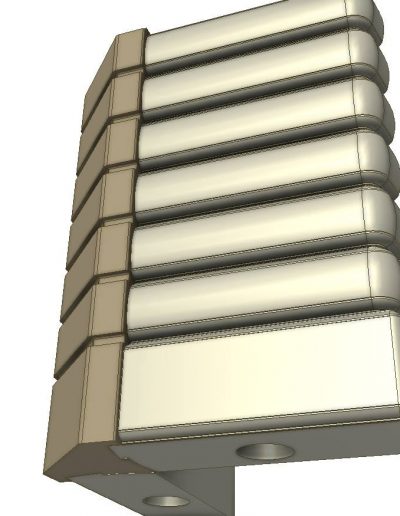

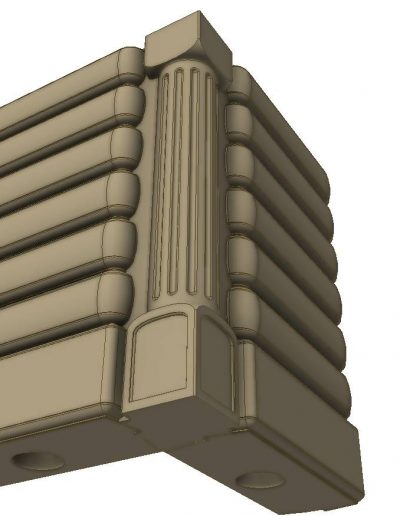

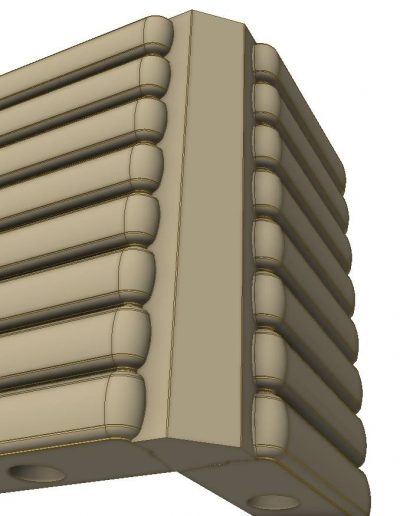

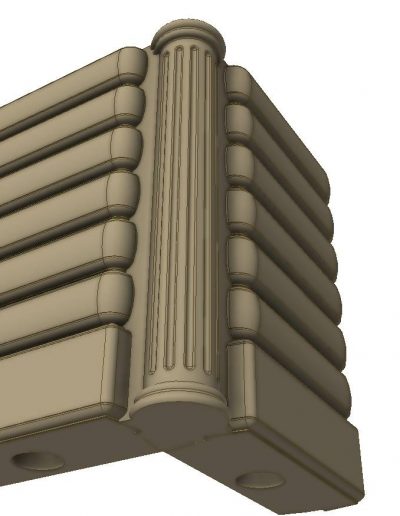

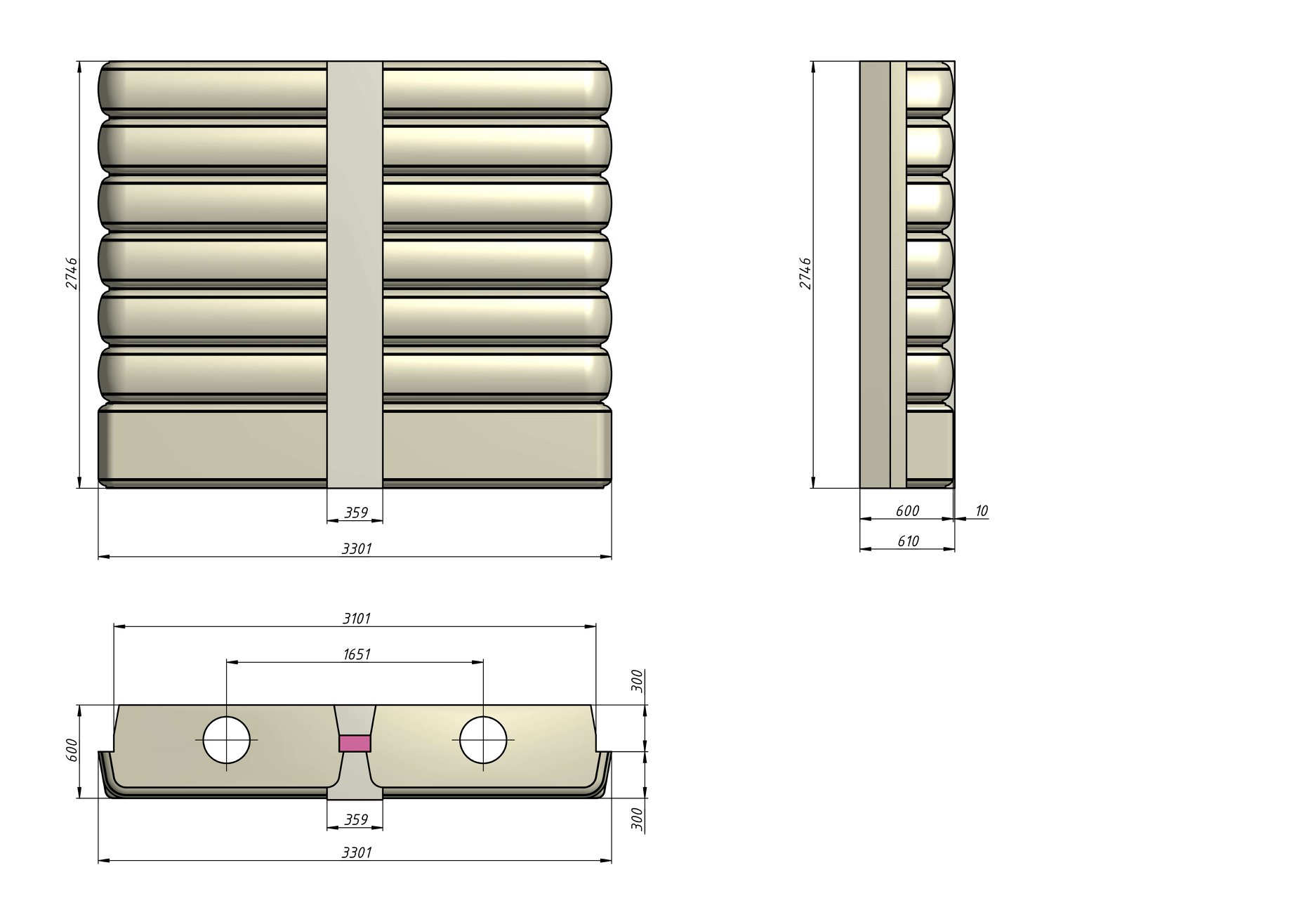

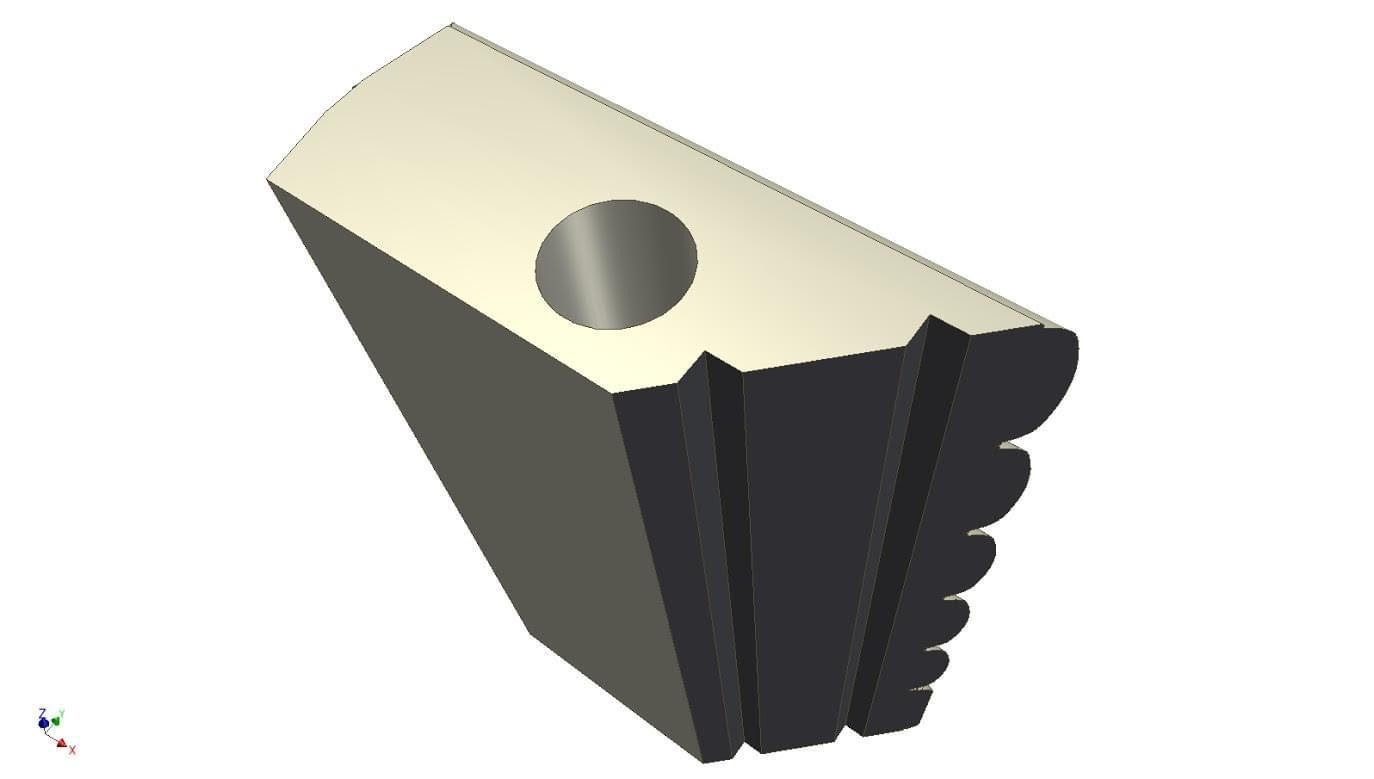

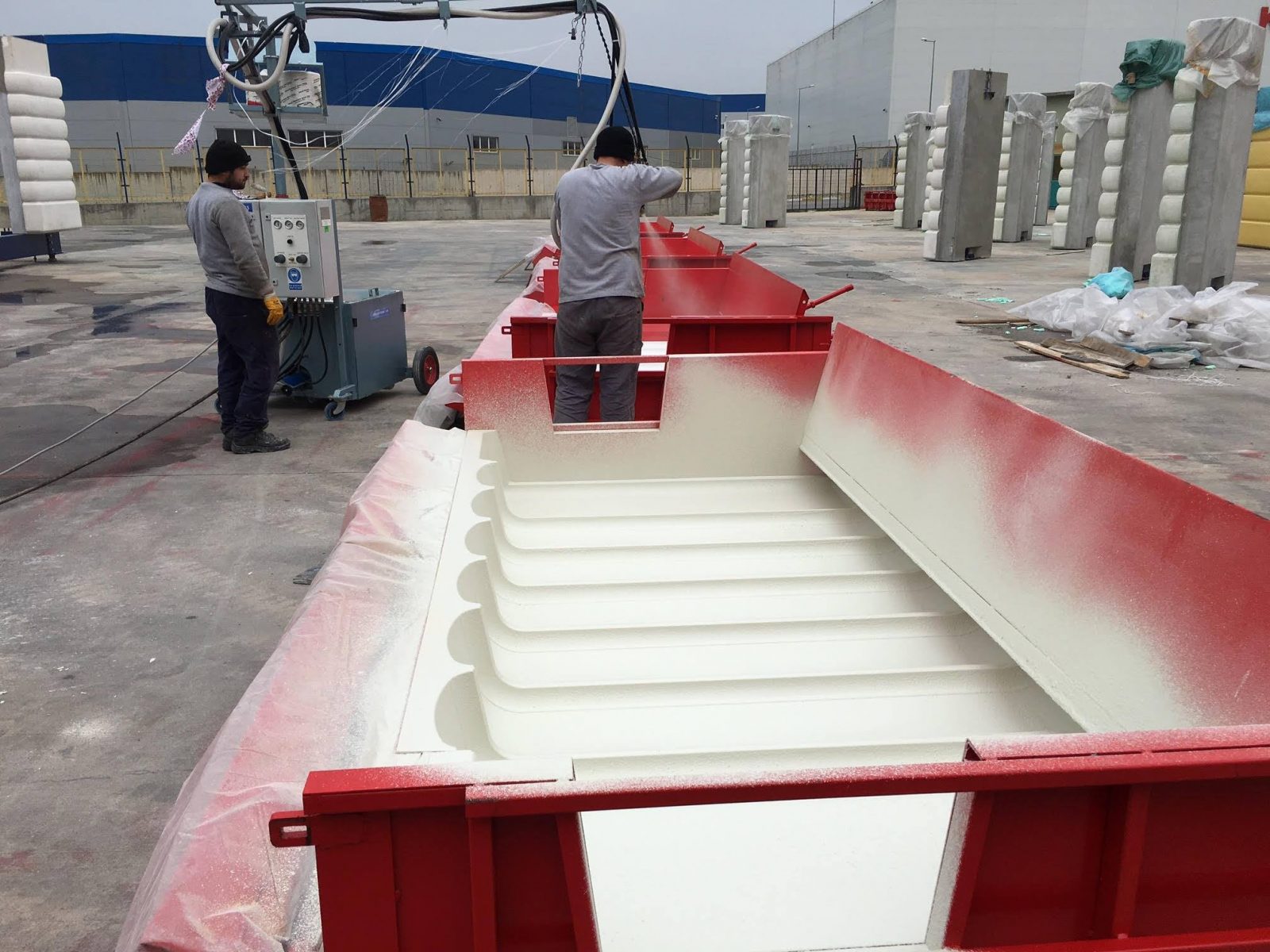

The steel molds are combined with plastic inserts. These thin reusable inserts form the outer surface of the wall panel. The inserts can be used hundreds of times, and once they start to deteriorate they can be crushed into plastic chips and used to make new molds. These repeated reuse of the plastic lowers the cost of panel production.

White cement is used for the finishing layer of the faсade, giving a high-quality surface.

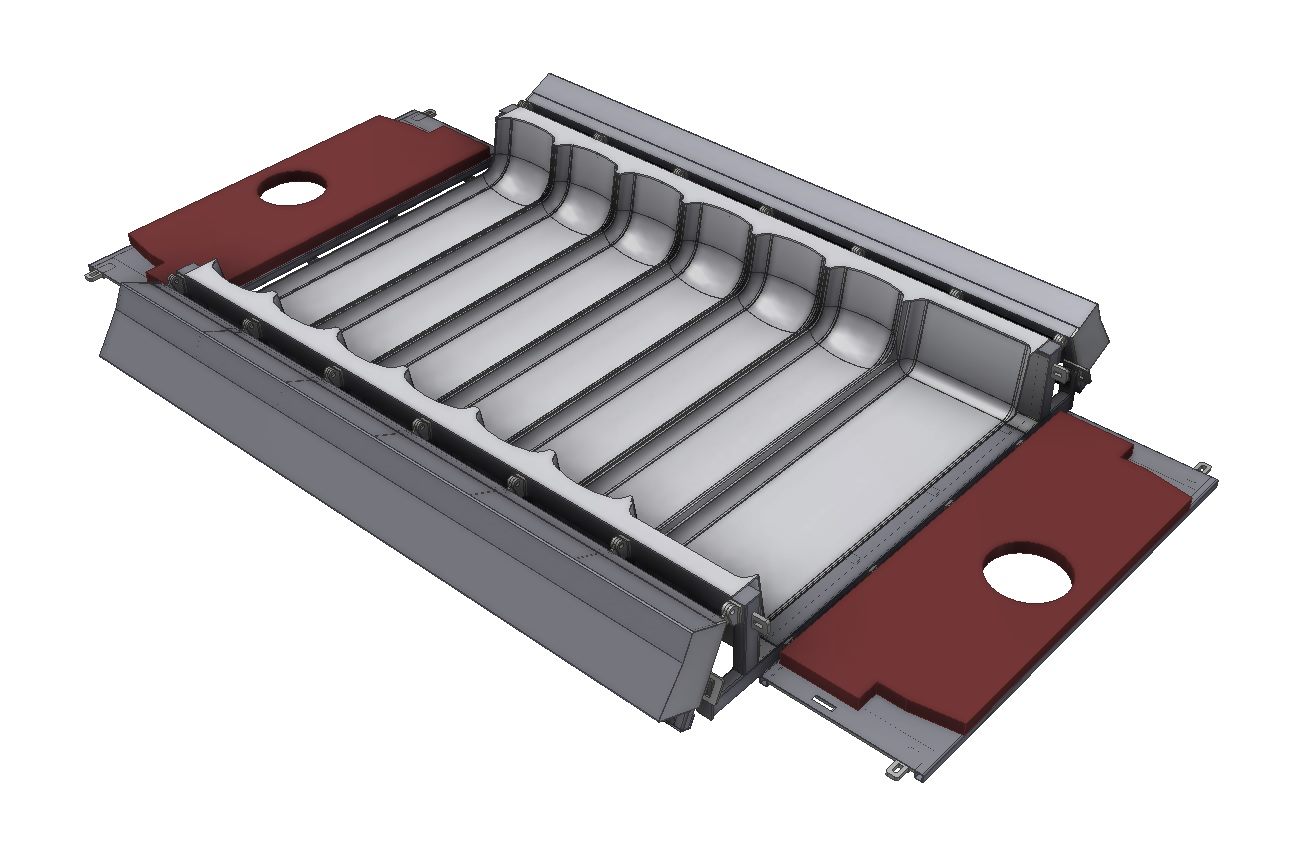

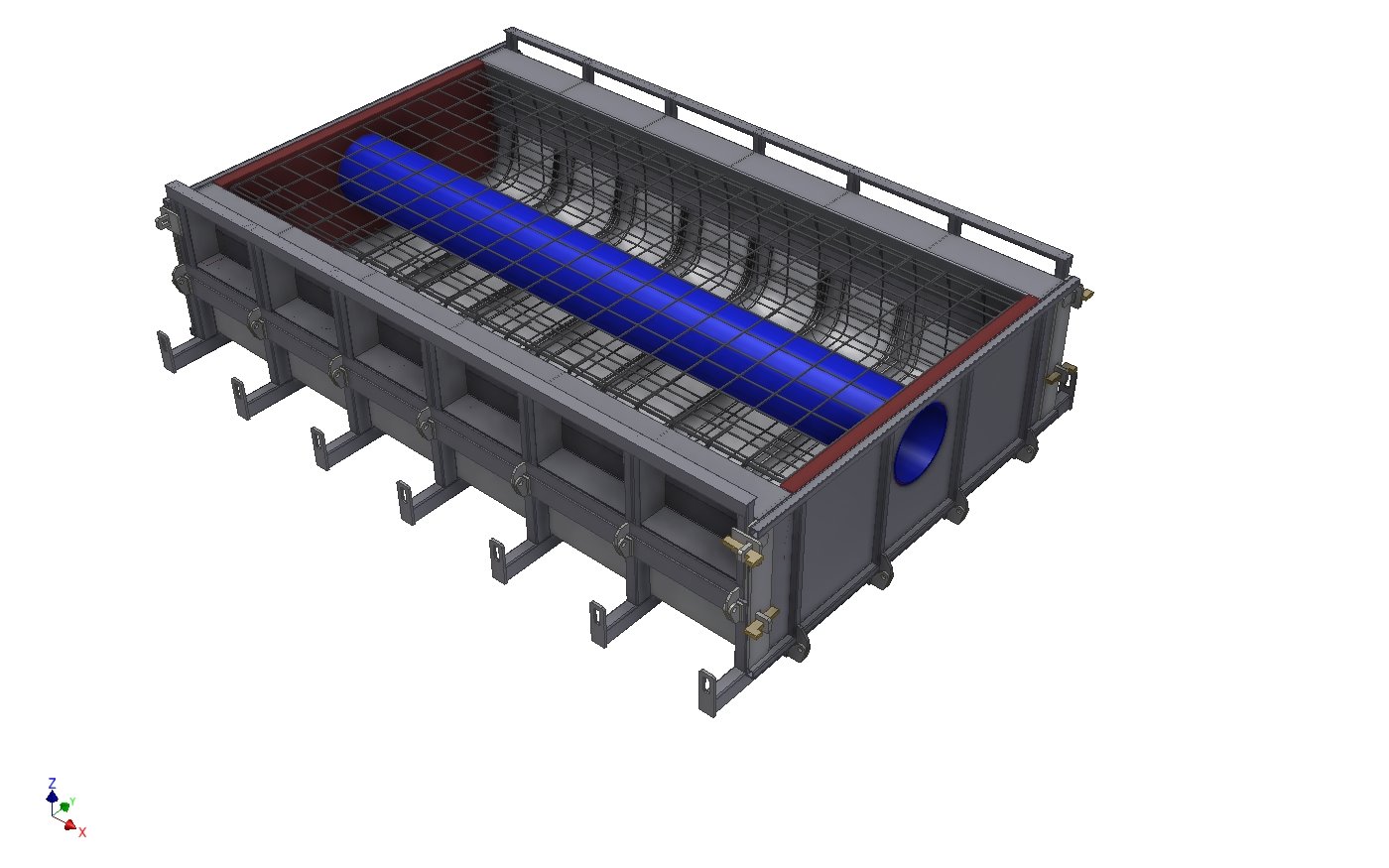

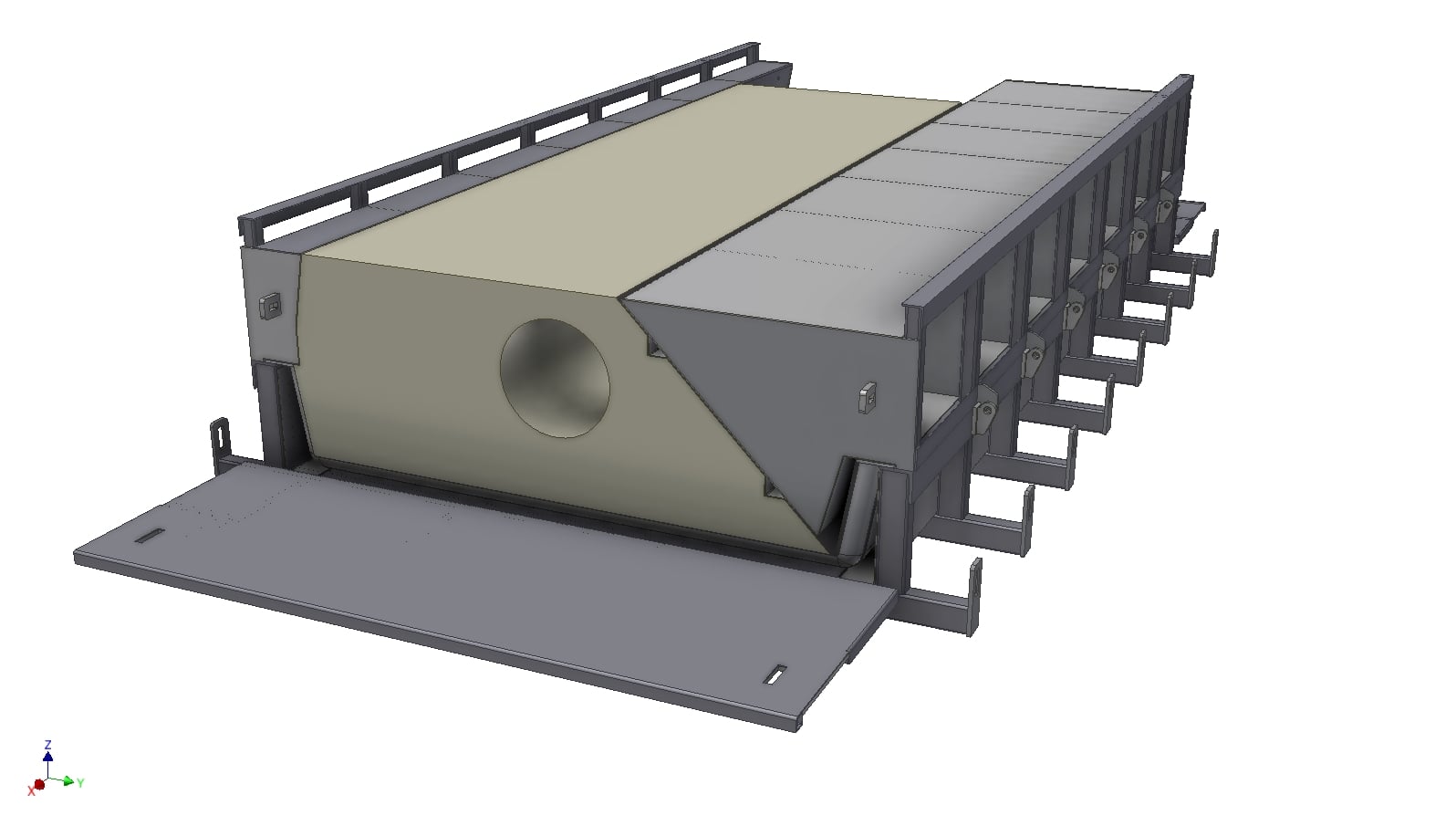

The molds are cast in a special facility. Each mold is first sprayed with a thin layer of fibre, the composite framework is inserted, and a ceramsite blend is poured on from above. Then vibration is applied, as well as vacuum processing, if required. All the installation details within the mold are already in place, including the ones that leave gaps for the columns.

The steel molds are combined with plastic inserts. These thin reusable inserts form the outer surface of the wall panel. The inserts can be used hundreds of times, and once they start to deteriorate they can be crushed into plastic chips and used to make new molds. These repeated reuse of the plastic lowers the cost of panel production.

White cement is used for the finishing layer of the faсade, giving a high-quality surface.

The molds are cast in a special facility. Each mold is first sprayed with a thin layer of fibre, the composite framework is inserted, and a ceramsite blend is poured on from above. Then vibration is applied, as well as vacuum processing, if required. All the installation details within the mold are already in place, including the ones that leave gaps for the columns.

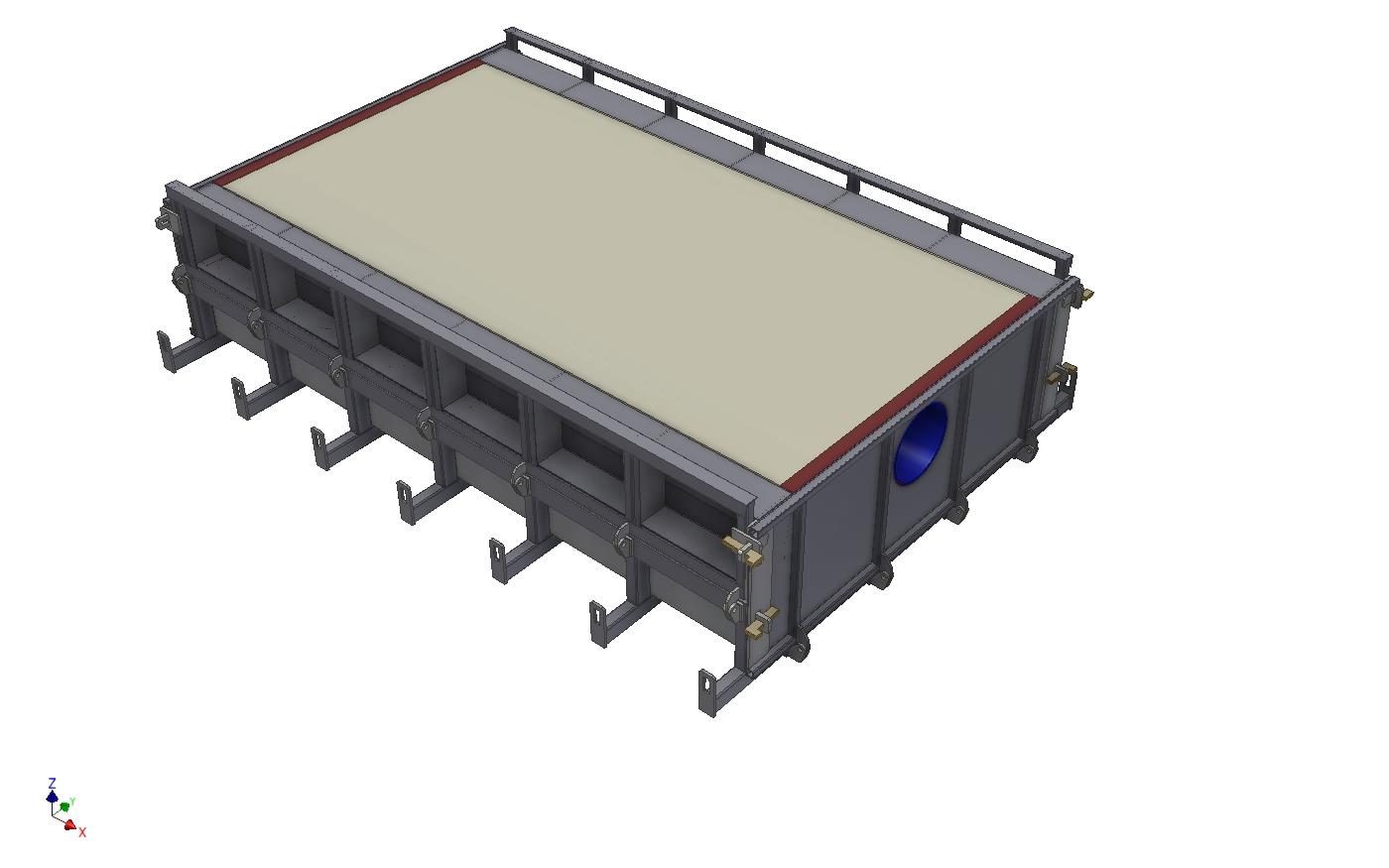

The panels are placed overnight in containers which also serve as steam chambers, where they acquire 40% resilience. The steam chamber takes account of the temperature required for white cement to set.

In the morning the demolding takes place; the steel molds and plastic inserts are returned for a repeat cycle, and the panels that are ready to be shipped are packed up and sent off to the site. Ordinary-weight trucks are used to transport them.

All these processes are almost completely automated, reducing manual labour to a minimum. As a result, one small factory can turn out roughly three thousand panels a day! This is enough to construct 50,000 square meters of housing per day, or 15 million square meters per year.

In the morning the demolding takes place; the steel molds and plastic inserts are returned for a repeat cycle, and the panels that are ready to be shipped are packed up and sent off to the site. Ordinary-weight trucks are used to transport them.

All these processes are almost completely automated, reducing manual labour to a minimum. As a result, one small factory can turn out roughly three thousand panels a day! This is enough to construct 50,000 square meters of housing per day, or 15 million square meters per year.

Video explaining how the technology works